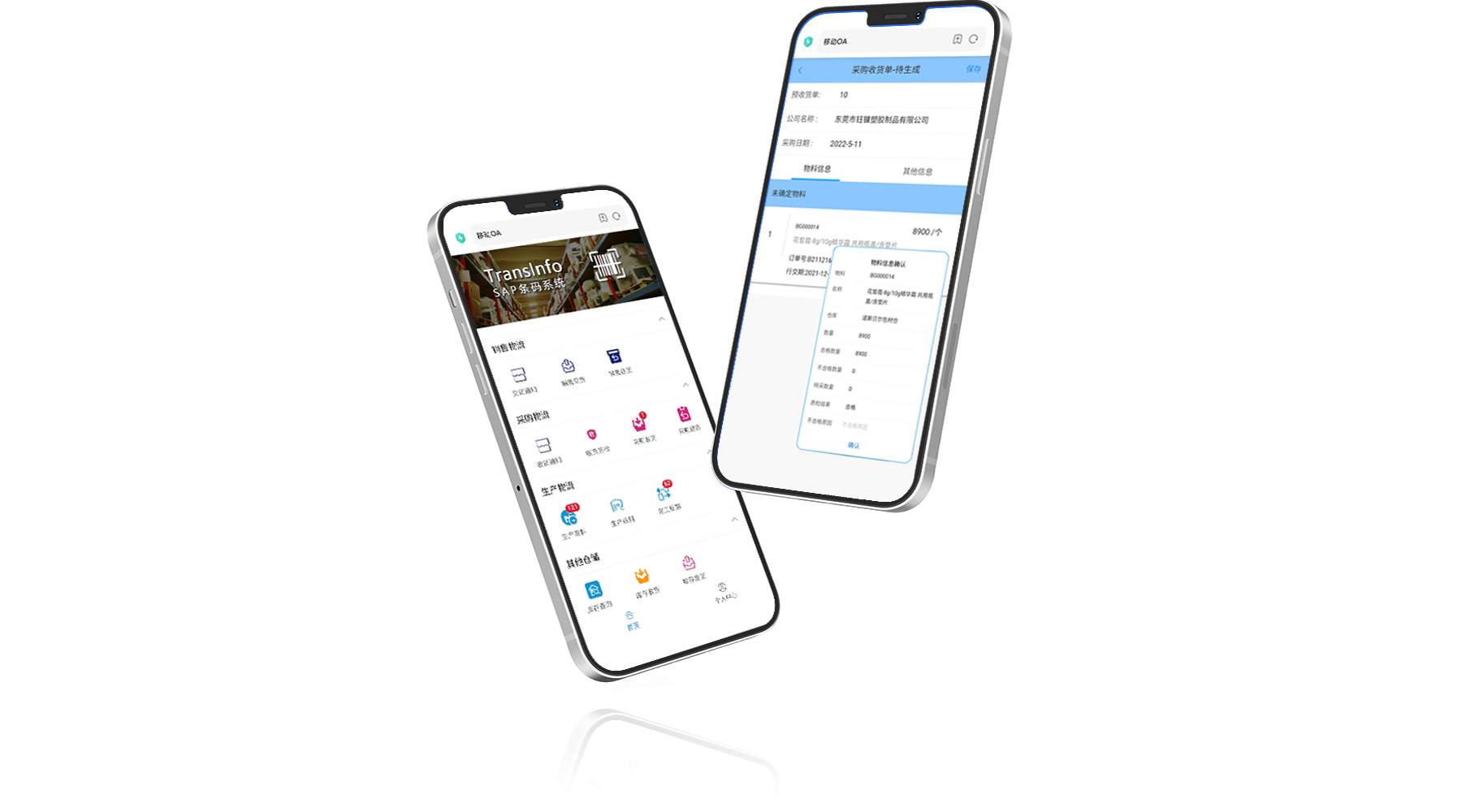

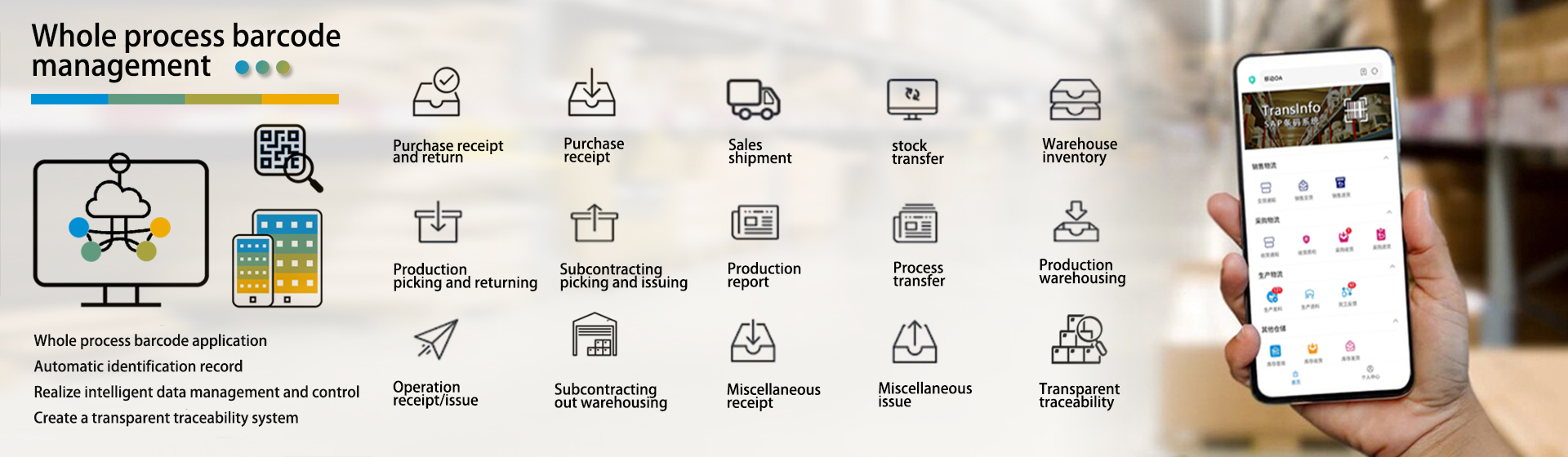

Functional components and value of TransInfo intelligent warehousing solution

In the cloud, efficient material control measures are implemented, and intelligent barcodes run through the entire business process.

Efficient business processing capability

Realize barcode control of key businesses such as partners, various documents, warehouses, and locations, greatly improving processing efficiency in practical work.

Real time grasp of inventory status

Comprehensively obtain the material status of various statuses such as circulation, production, and storage locations, achieve real-time data feedback, and achieve inventory warning, reasonably maintain and control enterprise inventory.

Business flow has traces to follow

By automatically collecting batch information, batch tracking and product traceability are achieved, enhancing the accuracy and timeliness of data, and achieving bidirectional traceability of product production or sales processes.

Standardize standard operating procedures

Utilizing barcode labels of materials to achieve automated data collection at all stages, automatically generating data with one click, standardizing operating procedures, reducing human intervention, and greatly reducing the probability of data errors.

Following the concept of first in, first out

Scientific coding of materials and storage locations, using barcode analysis to collect warehouse data, can quickly and accurately locate the location of materials, distinguish between old and new materials, and ultimately achieve the management goal of first in, first out.

Seamless integration with ERP system

Collaborate with SAP ERP system data in real-time to achieve more intuitive visual analysis reports on production progress, material conditions, etc., helping enterprises make reasonable planning.

Download

Download