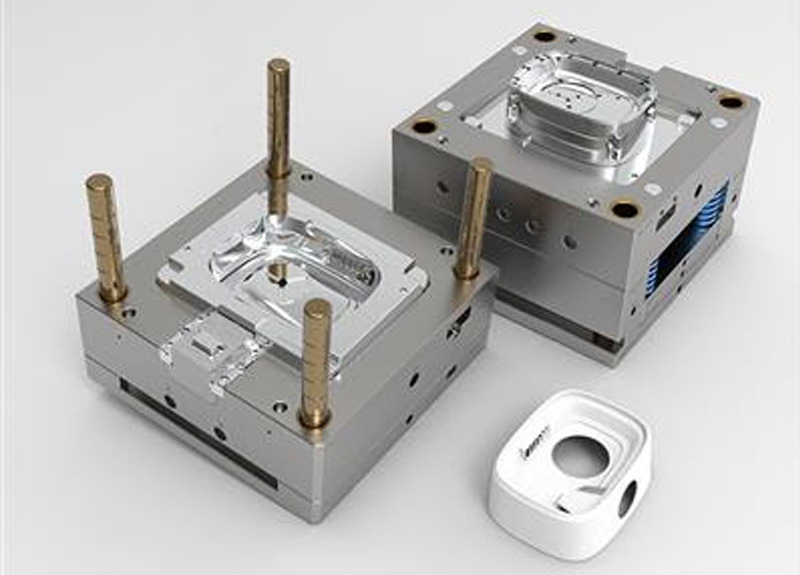

Provide complete quality control and management functions, covering all aspects of the entire supply chain, including procurement and receipt, warehouse inventory, work in progress, finished product shipment, and returns.

• Reward standard quality control system

The solution provides centralized quality control and inspection for all application modules. Based on materials and transaction types, enterprises can specify standard quality inspection plans to collect quality inspection results from the entire supply chain when actual business occurs.

• Flexible customization of quality control requirements

In the actual production process, enterprises can define quality control requirements for each processing stage and process. Quality control testing can be set by target values, maximum limits, and minimum limits. Multiple quality control tests can be combined to form a group to record results and report effectiveness.

• Multi stage quality control

In the early stage of production, you may need to test raw materials, in the middle stage, you may need to test process information such as temperature and time, and in the final stage, you may need to test the properties of the final product. For batch controlled products, the quality test results of the final product can be transformed into the specification properties of the product.

Download

Download