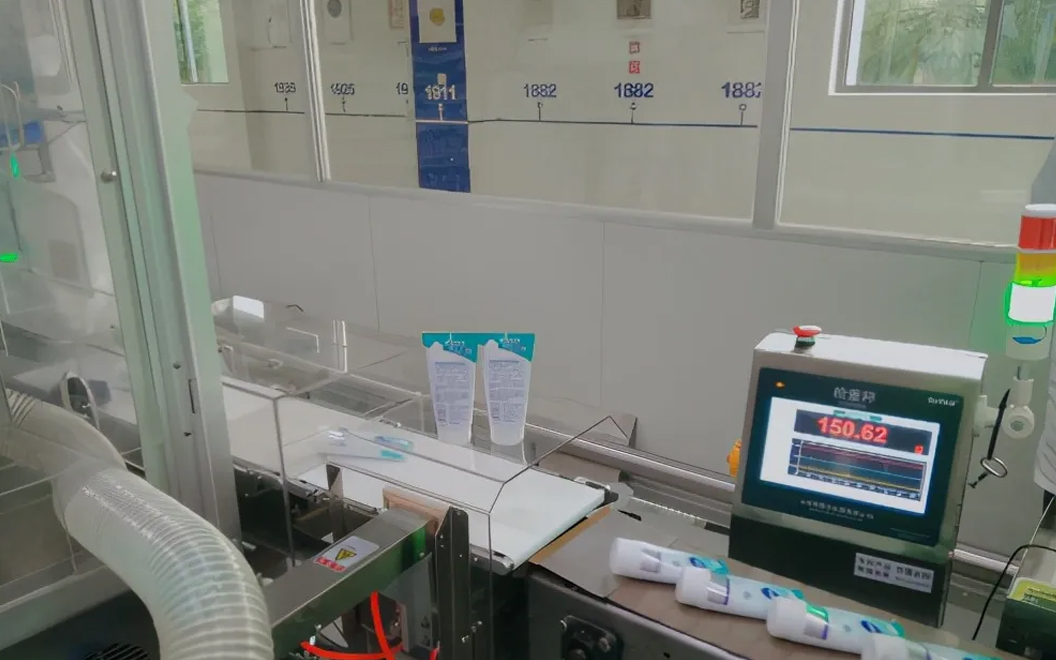

SAP ERP Solution for Daily Cosmetics Industry

With the upgrading of domestic consumption level, China's cosmetics market has become the largest emerging market in the world, and the cosmetics industry in China has developed from start-up to large-scale development, from simple and extensive to technological innovation and group management, forming a highly dynamic industrial army. The rapid development of the Internet has driven the upgrading of consumption methods and also impacted the updating and iteration of the cosmetics industry. How to maintain stable development in a fiercely competitive market environment, connect new technologies, manage increasingly complex consumer and product data, reduce business pressure, and improve competitiveness has become the optimization goal of cosmetics enterprises.

Download

Download